Role: 3D artist, UX designer

Circular Design

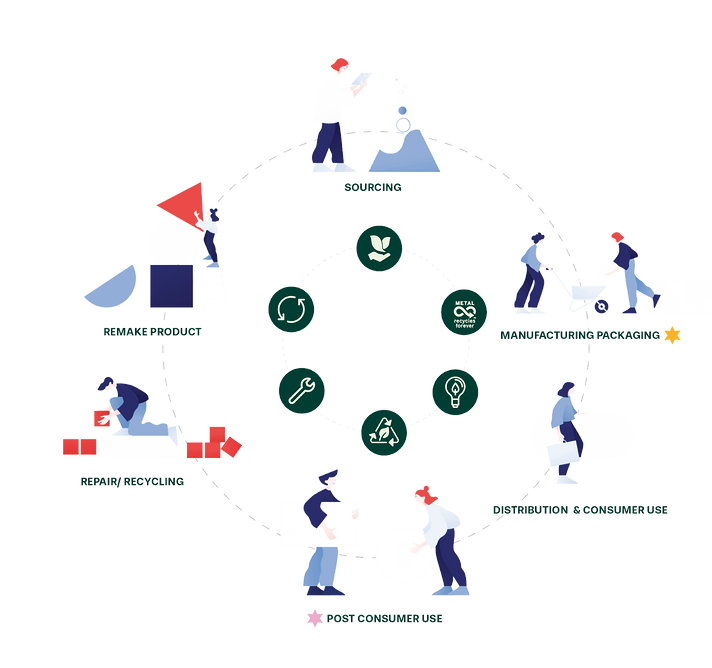

A project based on achieving a more sustainable and circular cosmetic supply chain

/ Project

Le Coeur is a circular design project that was carried out in collaboration with Nicola Arcenas and Valentina Madariaga during the fourth year of the Design degree at the University of Navarra.

The project as a whole covers, on a hypothetical level, the issue of including sustainable processes in the design of production, distribution and retail systems. For this project we proposed the concept of a brand for a cosmetics company that would include this type of process in all its stages, paying special attention to the perception and experience that the user would receive in his or her relationship with the product and the brand.

Help us reduce

waste.

Le Coeur

As reported on Refinery29 “The beauty industry produces 120 billion units of packaging each year. By 2050, there will be 12 billion tonnes of beauty packaging in landfill. It's just astonishing - and circular beauty is a positive step towards helping reduce our impact.” Today the European beauty industry is valued at €78.6 billion, making it one of, if not the largest cosmetics and personal care market in the world. Having this much value, it is no surprise that the industry has finally took the time to rethink its environmental impact. We now have Consumers right and left, calling brands out if they notice that ingredients or packaging is not recyclable, compostable or organic.

It is a given that all consumer products create environmental impacts throughout their life-cycles. Beauty products in particular are often needed to be packaged within containers that are made up of a number of different materials, including plastic, glass, recycled plastic, and aluminum. However, this use of mixed materials for a single item makes recycling complicated, and despite one’s best efforts to recycle them, many of those materials can wind up in landfills. More so today than ever, it is of crucial importance that products and processes be redesigned to minimise their environmental footprint. One’s eco friendly strategy must not only focus on the selection of ecological materials or less polluting processes, but on the circularity of the entire system.

Design brief

The key to our proposal lies in the minimization of our environmental footprint through a more mindful choice of materials and processes. Our number one priority is to set an example for environmental responsibility in the world of beauty.

The main lines of action we will follow to achieve this are: the use of the less materials (avoiding the creation of new materials), the choice of environmentally friendly materials and the maximization of reusage. We would like to create a brand that is zero waste through the sale of makeup refills and cases separately.

Many other aspects will be taken into consideration; for instance, minimizing the number of joints, fixings and fasteners and standardizing the types and sizes or the withdrawal of any unnecessary material used in the product or package.

Our main challenge as a brand is to be able to advocate for sustainability in all aspects while ensuring maximum affordability possible in order to make sustainability accessible to all.

This will be the source of our company’s brand differentiation regarding the competition in this sector. The few brands that manage to make sustainability compatible with affordability in their designs leave much to be desired in their aesthetics. We aim to achieve the compatibility of these four main pillars (aesthetics, sustainability, functionality and affordability) and procure a style that attracts both adults and young adults.

Our main challenge as a brand is to be able to advocate for sustainability in all aspects while ensuring maximum affordability possible in order to make sustainability accessible to all. This will be the source of our company’s brand differentiation regarding the competition in this sector. The few brands that manage to make sustainability compatible with affordability in their designs leave much to be desired in their aesthetics. We aim to achieve the compatibility of these four main pillars (aesthetics, sustainability, functionality and affordability) and procure a style that attracts both adults and young adults.

Customer need

Products.

LIPSTICK(01)

BLUSH(02)

EYE shadow(03)

FOUNDATION (04)

Technical feasibility

In order to go zero waste, there are steps that need to be taken first. At Le coeur, we stand by circular design. We selected materials that move towards an easier and less energy dependent manufacturing and recycling process.

Cosmetics casing.

In order to reduce waste, all makeup items will consist of a reusable casing made of aluminum. Eyeshadow, cream foundation and pressed powder will be placed in square metal pans. Whereas for the lipstick, a cylindrical case of the same type of aluminum will be used.

Cosmetic package box.

Refill

packaging.

Lipstick refill

packaging.

Makeup

ingredients.

Organic materials made up of natural ingredients, does not have heavy metals, is free of parabens and, above all, does not include petroleum derivatives.

Iterative stages.

Material Selection

1. Cosmetic casing

For the cosmetic casing we have evaluated different options such as glass, plastic and stainless steel. The following considerations were taken into account in our decision process:

+ The advantages of using glass: it would conserve the quality of the makeup; its reliability, in terms of protection, due to its impermeability. A glass container

would entail an outstanding barrier against externalities, the aroma and composition would remain intact. It is recyclable and loses none of its properties when recycled.

- The disadvantages of using glass: it is fragile, a strong impact could fracture the container making it useless and generating waste. Glass is also vulnerable to

temperature changes, it can shatter if exposed to cool water or air after heated. It is also heavier in comparison to paper, plastic or metal containers.

+ The advantages of using plastic: it is very resistant to corrosion, wear and tear. It is extremely light. Less energy is used to manufacture plastic than almost any

other packaging material. Less production cost and therefore more likely to have a lower price for the customer.

- The disadvantages of using plastic: plastic manufacturing causes a lot of pollution, it is not combinable, the mix of different plastic families results in a low

quality plastic. Although it can be recycled, it is not easy. The recycling process of plastic entails a high expense. It is not biodegradable, it can take hundreds of

years to disappear. It doesn’t resist to high temperatures.

+ The advantages of using stainless steel: maximum hygiene, less adhesion of dirt and external agents, quick surface cleaning, high durability, minimum maintenance, different finishes, avant-garde aesthetics, heat resistance, hypoallergenic for most skins.

- The disadvantages of using stainless steel: it is not easily moldable, the manufacture process requires energy and very high temperatures. It shows fingerprints and scratches. Stainless steel is not cost-efficient, being difficult to manufacture it usually comes with a steep price tag.

After considering all these materials, we have discarded glass and plastic because, although a very different levels, they can both easily generate waste and are poorly compatible with our goal of achieving a circular economy. Although stainless steel seemed like the best option, we had to hold on to our objective of making a brand that will bring the average customer closer to sustainability. This is why we opted for aluminum as an alternative to stainless steel. Aluminum is not as resistant as steel, but it is much lighter (almost a third of the steel). Both are highly recyclable and efficient with the environment. However, the difference that tipped the balance was that aluminum is much more economically accessible than stainless steel.

2. Product refill casing

For the selection of the product refill casing, we followed the same line of reasoning. As explained before, in order to make it easier to recycle and reduce manufacturing costs, we decided to make the casings of the same material: aluminum. The only item for which we had to adapt the material of its casing is the lipstick. Due to its fragility and consistency lipstick needs to be wrapped. At first, plastic seemed the only feasible option, but through research we found a greener alternative: a peelable biodegradable wax coating. The wax used for coating our products is made of paraffin blended with microcrystalline wax, which contains no Bisphenol.

3. Cosmetic package box

For the packaging box, plastic, recycled cardboard and molded pulp advantages and disadvantages were estimated. Our conclusion was that molded pulp/ fiber in clamshell packaging would be the best option. It presented more sustainable and recyclable qualities. In comparison with regular cardboard, we found that because of the clamshells rigid structure we would be able to fold it to open and close the packaging thus eliminating the need of a joint or glue to close or open the case.

4. Refill packaging

The refills would only need a simple package in order to be transported. We chose recycled cardboard because it had the level of rigidity that we needed for the content to be well preserved. The flatness of the cardboard package enables it to be easily stacked and transported.

5. Cosmetic ingredients

Our makeup will be made up of natural ingredients and not have heavy metals. It will be free of parabens and, above all, does not include petroleum derivatives. Le coeur uses natural ingredients, of which between 35 and 67% are from organic farming that is balanced with a minimum of artificial components. It is a balanced composition between the natural and the artificial, since if it were not this way, the product becomes very expensive and it cannot reach all of our consumer market. Our aim however is to be a 100% ecological in the future, which will happen, but we will still need to find a way of producing our makeup without increasing our price factor.

Circular

Le Coeur

Making our supply chain circular, we provide refillable makeup to avoid the production of new materials every time a new product is made. Also, as the materials used for packaging are all uniformed, when needed to be recycled the same product can be used agains to remake more package.

We have oriented our manufacture process towards reducing the components to the minimum as possible. Besides securing less material waste, we have decided not to add any labels to our product other than the separate piece of paper with the ingredients and instructions.

For our cosmetics casing, we would partner with the Metal Packaging Europe (MPE) that would allow us to join in their initiative towards a more circular economy within the metal packaging field. We would be more closely attached with Ardagh Group, that would particularly manufacture all our comestics metal casing. For our Refill Packaging and Cosmetic Packaging as well, we would partner with UFP Technologies Inc., that could provide our Molded Fiber/ Pulp Packaging (Clamshells). The use of biodegradable, recyclable and reusable packaging id brty modular, if certain pieces of the packaging were to break or get damaged, we will offer repair services when brought to the store.

Jigs and fixtures

Our designs are shaped by the principle of modularity so that assemblies and sub-assemblies can be built independently. We have also avoided the use of permanent joining methods and reduced the number of joints to a minimum. In fact, the only pieces that require assemblies are the makeup cases, one per case. These will be one-piece joints placed on the top corner of the case, and will function as a point of axis to rotate or slide the cover of the case to a side. This opening system as opposed to the traditional one, reduces the number of joints needed to one per item.

No ink will be used either in the package nor in the product itself. Ink will only be applied on to a separate piece of paper that will be placed below the product inside of the refill packaging. It will include detailed information about ingredients, instructions and other specifications. As for the cases, no labels will be used, as the logo will be embossed directly on the surface.

Design decisions

All of Le coeur items and cases have the same shape (square with rounded edges), this will ease the manufacturing process as the die cuts will be fewer. By removing the corners we also have reduced the use of the material to the minimum needed.

Manufacture process

We have oriented our manufacture process towards reducing the components to the minimum as possible. Besides securing less material waste, we have decided not to add any labels to our product other than the separate piece of paper with the ingredients and instructions. The only other process in manufacturing our package other than the preparation of the compost and the die cutting would be the embossing of the logo onto the surface of the products.

Assemblies

We avoided the use of fasteners to help with the disassembling process for the end-of-life processing. The assemblies will be made of aluminum to use one sole material and for it not to be necessary to be disassembled in order to be recycled (the aluminum could just be melted in order to turn it into another product).

Transport

In our distribution transport, we will shift from road to rail or air to sea. We will also hopefully use hybrid or electric vehicles or larger container trucks that will help reduce the emissions associated with the transport of cosmetics. Furthermore, the sleek and compact design of all our packaging allows more product to fit in container trucks, thus lessening the number of transports

done.

Finishing and coating